In order to reach the inaccessible region of the body, the demand for tiny sensors in the medical field is increasing. Therefore, the designers also focusing on the technological development of the production of miniature coils and ultra-fine wires. Invasive sensors in the medical field help the doctor to treat cryo cancer treatment through the elimination of the tumors, to reach the parts of the body that are otherwise unapproachable.

The most significant challenge that the designers are facing is that how to fit the physical size of the invasive medical devices within the body region. As the medical professionals make the invasive devices enter into the body through catheters, permanent or temporary implants, and minimally inversive procedures, therefore, the designers need to focus on the continuous miniaturization process so that sensors can reach inaccessible regions effectively. Designers also focus on minimizing energy consumption, lessen the disturbance of body functioning, and enhancing the lifetime of the devices.

Why the Sensors in the Medical Field are important?

The sensors in the medical field that use the technology of micro-coil winding are important due to several factors such as-

- In order to monitor, log, and control data through the miniature implantation.

- To transfer energy to the implants so that the requirement of battery charging is fulfilled. In order to activate and operate systems, it is also important to provide electrical charge input.

- In heat treatments, electromagnetic radiation-based treatments, and RF treatments sensors are useful for radiating energy.

- To employ an external or local magnetic field for In-vivo magnetic 3D navigation, sensors are valuable.

Manufacturing Process:

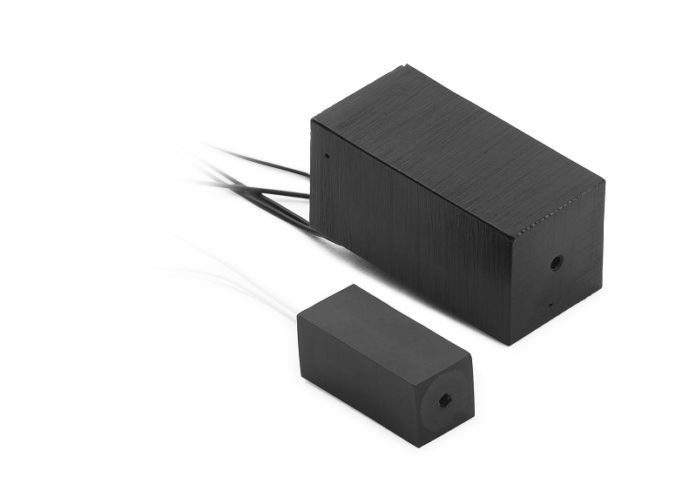

As the manufacturing of sensors involves the manufacturing of the micro-coils, it is important to investigate the micro-coil winding process. In order to make sensors, designers focus on the electromagnetic and geometric requirements of the clients. Therefore, modern manufacturers tend to use ultra-fine copper wire to prepare micro-coils with a manufacturing size of 59 AWG (9 microns or 0.009 mm.). In order to make fine sensors, designers now develop a typical micro-coil that can consist of 1000 windings of a cross-sectional area smaller than a pin.

On the other hand, the preparation of sensors may involve connecting the ultra-fine wires of different thicknesses. Through Thermo-Compression Bonding technology, manufacturing companies are now able to connect an ultra-fine wire with another ultra-fine wire of 3-4 times thicker. This technology is effective to provide corrosion-free, high reliable, and strain-free connectivity. These connections help to simplify and lower the processing costs that were quite impossible using the micro soldering process. It is important to note that the clients can inspect the manufacturing process and the manufacturers also need to follow ISO 13485.

Application of the Sensors in the Medical Field:

- Diagnostics: Glycemic, physiological, and flow sensors help in wireless communication through miniature implants.

- Therapeutic Application: In electricity-based ablations and electrophysiological treatments sensors are effective.

- Navigation and Orientation: In order to detect stents positioning, targeted radiation catheters, targeted drug delivery, highly accurate ablations, inter-body tagging, and implanted markers, sensors are effective. Sensors in the medical field also have significant usage in gastroscopic, colonoscopic, endoscopic, laparoscopic, etc.